| Availability: | |

|---|---|

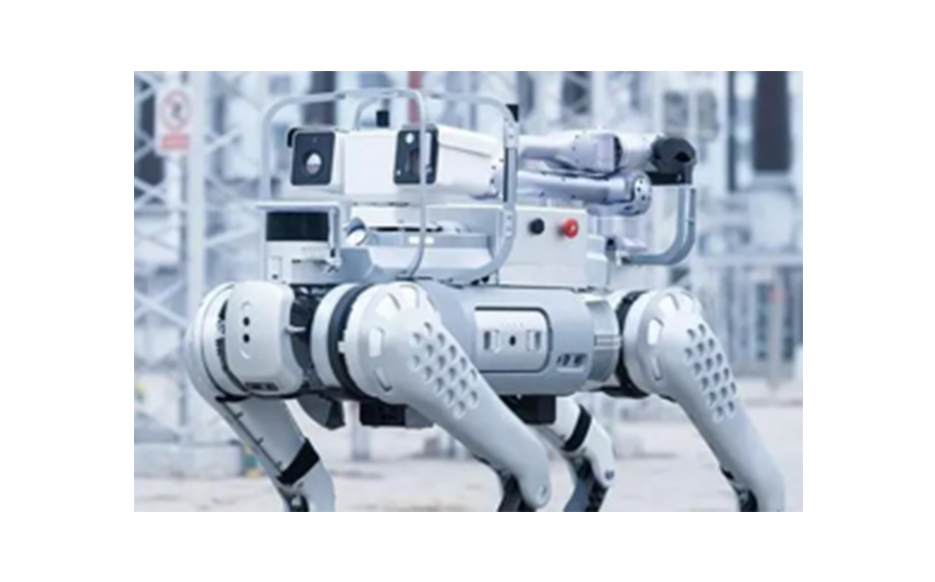

The Heavy-Duty Rough-Terrain Legged Robot is a specialized intelligent equipment developed by IMS (Jinan) Robot Technology Co., Ltd., targeting heavy-load operations and ultra-rough terrain scenarios. Unlike traditional wheeled or tracked robots, its multi-joint legged structure enables flexible adaptation to extreme terrains such as rocky slopes, rubble piles, and uneven construction sites. With a maximum load capacity of 100kg, this robot integrates heavy-duty transportation, high-altitude inspection, and multi-sensor monitoring, making it a core tool for industries such as construction, mining, and heavy metallurgy. It not only reduces manual labor intensity but also eliminates safety risks in high-risk, heavy-load operations, aligning with the national "intelligent construction" development strategy promoted by the Ministry of Housing and Urban-Rural Development.

With a maximum load capacity of 100kg, the robot can transport heavy materials such as construction steel bars, mechanical parts, and maintenance tools in rough terrain. Its leg structure distributes weight evenly, avoiding sinking in soft soil or sand, which is a common issue with wheeled robots. It is an ideal replacement for manual handling in high-altitude or dangerous areas (e.g., mine tunnels, high-rise construction sites).

Equipped with 6 multi-joint legs (each with 3 degrees of freedom), the robot can:

Adjust the length and angle of each leg in real time according to terrain changes (e.g., stepping over 300mm-high obstacles, climbing ≤25° slopes).

Maintain body balance on uneven surfaces (e.g., rocky ground, rubble piles) through gyroscope and pressure sensor feedback.

This ensures stable movement even in terrains where tracked or wheeled robots cannot operate.

Integrated with a multi-functional sensor system to address complex on-site risks:

High-Definition Camera: Captures high-resolution images of high-altitude equipment (e.g., building outer walls, mine shaft tops) for defect detection (e.g., cracks, corrosion).

Hazardous Gas Detector: Monitors CH₄, H₂S, and CO concentrations in real time, with automatic shutdown and alarm if toxic or flammable gas levels exceed standards.

Acoustic Sensor: Identifies abnormal sounds from heavy equipment (e.g., gear wear, bearing failure) by comparing with pre-trained acoustic models, enabling predictive maintenance.

The robot’s top-mounted lifting mechanism supports customizable stroke lengths (0.5-2m) to meet different application needs:

Construction Industry: Lifting and installing strip panels (cooperating with IMS’s strip panel installation robot) to replace manual high-altitude operations.

Mining Industry: Lifting detection equipment to inspect the top of mine shafts for water seepage or structural damage.

Metallurgy Industry: Lifting temperature probes to measure the temperature of high-temperature furnaces, avoiding manual exposure to extreme heat.

The robot’s body is made of high-strength aluminum alloy and anti-corrosion coating, enabling it to withstand:

Extreme temperatures (-35~65℃), suitable for cold northern mining areas and high-temperature southern construction sites.

High humidity (up to 95%) and dusty environments, with dust-proof and waterproof ratings of IP65.

This ensures long-term stable operation in harsh industrial conditions.

The Heavy-Duty Rough-Terrain Legged Robot is a key equipment for intelligent upgrading in heavy industries:

Construction Industry: Aligning with the "Intelligent Construction Pilot Cities" (e.g., Beijing, Shanghai, Guangzhou) policy, it is used for high-altitude strip panel installation, heavy material transportation on construction sites, and safety inspection of building structures (e.g., detecting cracks on outer walls).

Mining Industry: Underground mine material transportation, shaft inspection, and gas concentration monitoring, reducing the risk of accidents such as collapses or gas explosions.

Metallurgy Industry: Transportation of high-temperature smelting materials, inspection of blast furnace linings, and detection of pipeline corrosion in steel plants, improving production safety.

Emergency Rescue: Post-disaster (e.g., earthquake, flood) search and rescue operations, entering dangerous areas to transport medical supplies or detect survivor signals without endangering rescuers.

A1: The standard maximum load capacity is 100kg. For specific user needs, IMS can provide customized solutions (e.g., strengthening the leg structure, optimizing the power system) to increase the load capacity to 150kg, but this may slightly reduce the working duration.

A2: Each leg is equipped with pressure sensors and a high-precision gyroscope. The robot’s control system calculates the terrain slope and obstacle height in real time, adjusts the lifting height and angle of each leg, and ensures the body remains horizontal—similar to how humans maintain balance when walking on rough ground.

A3: Yes. With a customizable lifting mechanism (stroke up to 2m), the robot can lift tools or cameras to heights of 3-5m (by combining its own height) for high-altitude inspection or installation. It is widely used in high-rise building construction and power tower inspection.

A4: The 24V40Ah ternary lithium battery takes about 3-4 hours to fully charge using a dedicated fast charger. Under normal use (8 hours per day, 5 days per week), the battery service life is 2-3 years, and IMS provides battery replacement and maintenance services.

The Heavy-Duty Rough-Terrain Legged Robot is a specialized intelligent equipment developed by IMS (Jinan) Robot Technology Co., Ltd., targeting heavy-load operations and ultra-rough terrain scenarios. Unlike traditional wheeled or tracked robots, its multi-joint legged structure enables flexible adaptation to extreme terrains such as rocky slopes, rubble piles, and uneven construction sites. With a maximum load capacity of 100kg, this robot integrates heavy-duty transportation, high-altitude inspection, and multi-sensor monitoring, making it a core tool for industries such as construction, mining, and heavy metallurgy. It not only reduces manual labor intensity but also eliminates safety risks in high-risk, heavy-load operations, aligning with the national "intelligent construction" development strategy promoted by the Ministry of Housing and Urban-Rural Development.

With a maximum load capacity of 100kg, the robot can transport heavy materials such as construction steel bars, mechanical parts, and maintenance tools in rough terrain. Its leg structure distributes weight evenly, avoiding sinking in soft soil or sand, which is a common issue with wheeled robots. It is an ideal replacement for manual handling in high-altitude or dangerous areas (e.g., mine tunnels, high-rise construction sites).

Equipped with 6 multi-joint legs (each with 3 degrees of freedom), the robot can:

Adjust the length and angle of each leg in real time according to terrain changes (e.g., stepping over 300mm-high obstacles, climbing ≤25° slopes).

Maintain body balance on uneven surfaces (e.g., rocky ground, rubble piles) through gyroscope and pressure sensor feedback.

This ensures stable movement even in terrains where tracked or wheeled robots cannot operate.

Integrated with a multi-functional sensor system to address complex on-site risks:

High-Definition Camera: Captures high-resolution images of high-altitude equipment (e.g., building outer walls, mine shaft tops) for defect detection (e.g., cracks, corrosion).

Hazardous Gas Detector: Monitors CH₄, H₂S, and CO concentrations in real time, with automatic shutdown and alarm if toxic or flammable gas levels exceed standards.

Acoustic Sensor: Identifies abnormal sounds from heavy equipment (e.g., gear wear, bearing failure) by comparing with pre-trained acoustic models, enabling predictive maintenance.

The robot’s top-mounted lifting mechanism supports customizable stroke lengths (0.5-2m) to meet different application needs:

Construction Industry: Lifting and installing strip panels (cooperating with IMS’s strip panel installation robot) to replace manual high-altitude operations.

Mining Industry: Lifting detection equipment to inspect the top of mine shafts for water seepage or structural damage.

Metallurgy Industry: Lifting temperature probes to measure the temperature of high-temperature furnaces, avoiding manual exposure to extreme heat.

The robot’s body is made of high-strength aluminum alloy and anti-corrosion coating, enabling it to withstand:

Extreme temperatures (-35~65℃), suitable for cold northern mining areas and high-temperature southern construction sites.

High humidity (up to 95%) and dusty environments, with dust-proof and waterproof ratings of IP65.

This ensures long-term stable operation in harsh industrial conditions.

The Heavy-Duty Rough-Terrain Legged Robot is a key equipment for intelligent upgrading in heavy industries:

Construction Industry: Aligning with the "Intelligent Construction Pilot Cities" (e.g., Beijing, Shanghai, Guangzhou) policy, it is used for high-altitude strip panel installation, heavy material transportation on construction sites, and safety inspection of building structures (e.g., detecting cracks on outer walls).

Mining Industry: Underground mine material transportation, shaft inspection, and gas concentration monitoring, reducing the risk of accidents such as collapses or gas explosions.

Metallurgy Industry: Transportation of high-temperature smelting materials, inspection of blast furnace linings, and detection of pipeline corrosion in steel plants, improving production safety.

Emergency Rescue: Post-disaster (e.g., earthquake, flood) search and rescue operations, entering dangerous areas to transport medical supplies or detect survivor signals without endangering rescuers.

A1: The standard maximum load capacity is 100kg. For specific user needs, IMS can provide customized solutions (e.g., strengthening the leg structure, optimizing the power system) to increase the load capacity to 150kg, but this may slightly reduce the working duration.

A2: Each leg is equipped with pressure sensors and a high-precision gyroscope. The robot’s control system calculates the terrain slope and obstacle height in real time, adjusts the lifting height and angle of each leg, and ensures the body remains horizontal—similar to how humans maintain balance when walking on rough ground.

A3: Yes. With a customizable lifting mechanism (stroke up to 2m), the robot can lift tools or cameras to heights of 3-5m (by combining its own height) for high-altitude inspection or installation. It is widely used in high-rise building construction and power tower inspection.

A4: The 24V40Ah ternary lithium battery takes about 3-4 hours to fully charge using a dedicated fast charger. Under normal use (8 hours per day, 5 days per week), the battery service life is 2-3 years, and IMS provides battery replacement and maintenance services.